On the border of cybernetics and economics

We are experimenters, engineers and scientists. It is important for us not only to develop a solution that is relevant for today, but first to understand the scientific validity of the approach and achieve clarity in the presentation of the principles that should underlie the entire architecture of a software solution.

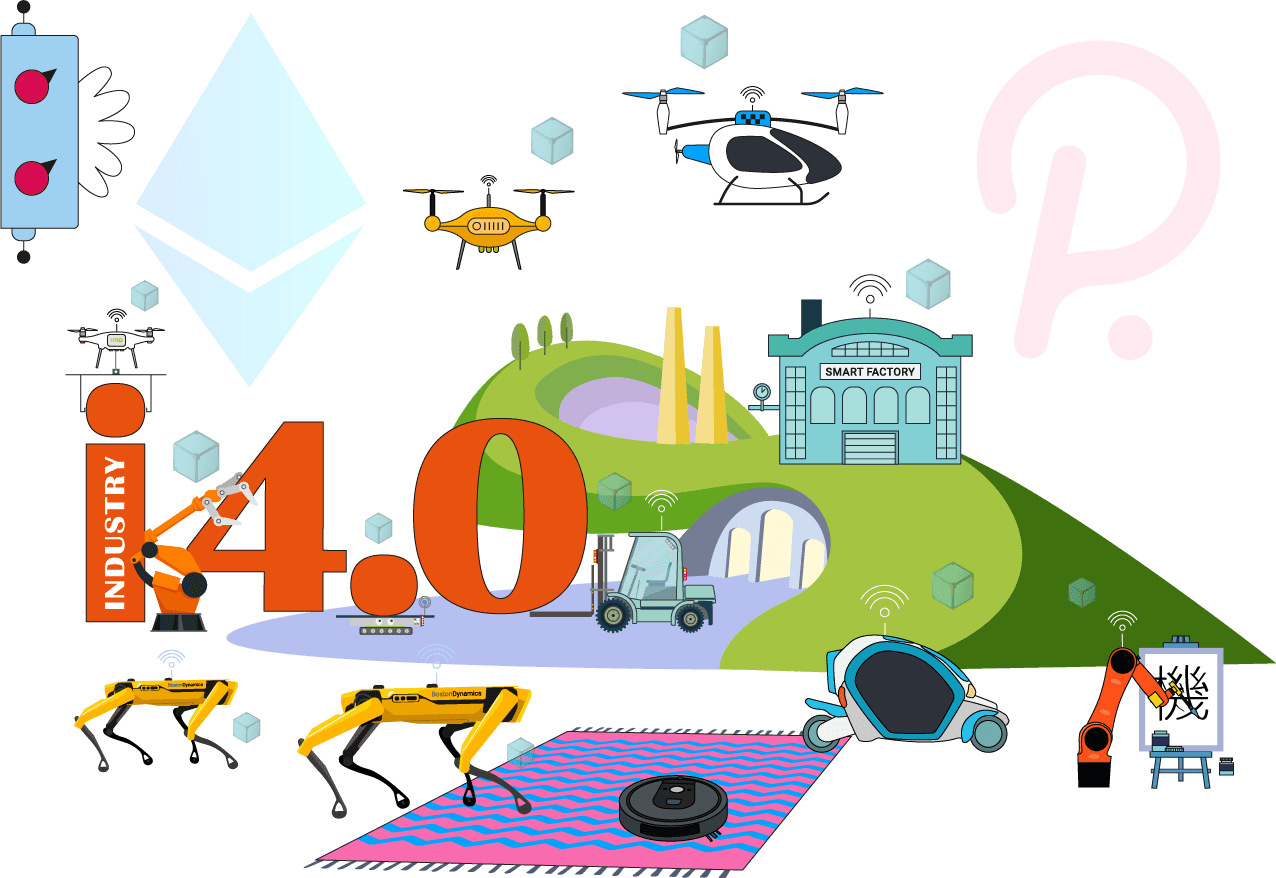

Since 2017 we publish research articles representing to the academic community concepts united by the idea of the robot economy. Below we would like to present the most general, important explanation why the robot economy is an inevitable and obvious solution in the wake of the new industrial revolution.

ROBONOMICS PARACHAIN CROWDLOAN STARTED

ROBONOMICS PARACHAIN CROWDLOAN STARTED